Leave Your Message

In the ever-evolving landscape of industrial materials, the selection and maintenance of High Chrome Cast Iron are pivotal for enhancing durability and performance in various applications. High Chrome Cast Iron, known for its excellent wear resistance and strength, is particularly valued in industries such as mining, cement, and recycling. According to a recent industry report by the Materials Engineering Association, the demand for high-performance materials like High Chrome Cast Iron is projected to grow by 15% annually through 2025, driven by the need for enhanced product longevity and reduced operational costs.

As highlighted by Dr. Alice Thompson, a leading expert in materials science, “The strategic implementation of High Chrome Cast Iron not only boosts the lifespan of industrial components but also significantly minimizes downtime and maintenance costs.” Her insights underscore the critical importance of meticulous selection and proactive maintenance of High Chrome Cast Iron products. This guide aims to equip professionals with essential knowledge and best practices to make informed choices and extend the service life of their high-performance components, ensuring they meet the rigorous demands of modern applications. With the right approach, High Chrome Cast Iron can deliver exceptional value and reliability, reinforcing its vital role in contemporary industry.

High chrome cast iron, known for its exceptional wear resistance and durability, is widely utilized in abrasive environments such as mining, construction, and manufacturing. This material typically contains chromium levels ranging from 12% to 30%, which enhances its hardness and wear resistance. According to a report by the International Journal of Materials Science, high chrome cast iron can achieve a hardness of up to 60 HRC (Rockwell Hardness Scale), making it an ideal choice for components subjected to severe abrasion.

The properties of high chrome cast iron stem from its unique microstructure, which includes a high volume of chromium carbides in a matrix of martensite. This combination not only provides superior resistance to wear but also contributes to its toughness, enabling it to withstand impact forces without cracking. Research published in the Metallurgical and Materials Transactions highlights that the increased chromium content leads to improved oxidation resistance and thermal stability, allowing parts to perform reliably under fluctuating temperatures and harsh conditions.

When choosing high chrome cast iron for applications, it's crucial to consider factors such as the working environment, expected loads, and the specific wear mechanisms involved. Proper maintenance, including regular inspection and timely replacement of worn components, can significantly extend the lifespan of parts made from high chrome cast iron. Adhering to these guidelines ensures optimal performance and durability, making high chrome cast iron a valuable investment for industries reliant on robust materials.

| Property | Value |

|---|---|

| Chromium Content | High (12-30%) |

| Hardness | 58-66 HRC |

| Tensile Strength | 700-1400 MPa |

| Impact Toughness | 10-20 J |

| Corrosion Resistance | Excellent |

| Typical Applications | Mining, Oil & Gas, Power Generation |

| Maintenance Tips | Regular Cleaning, Inspection, Proper Storage |

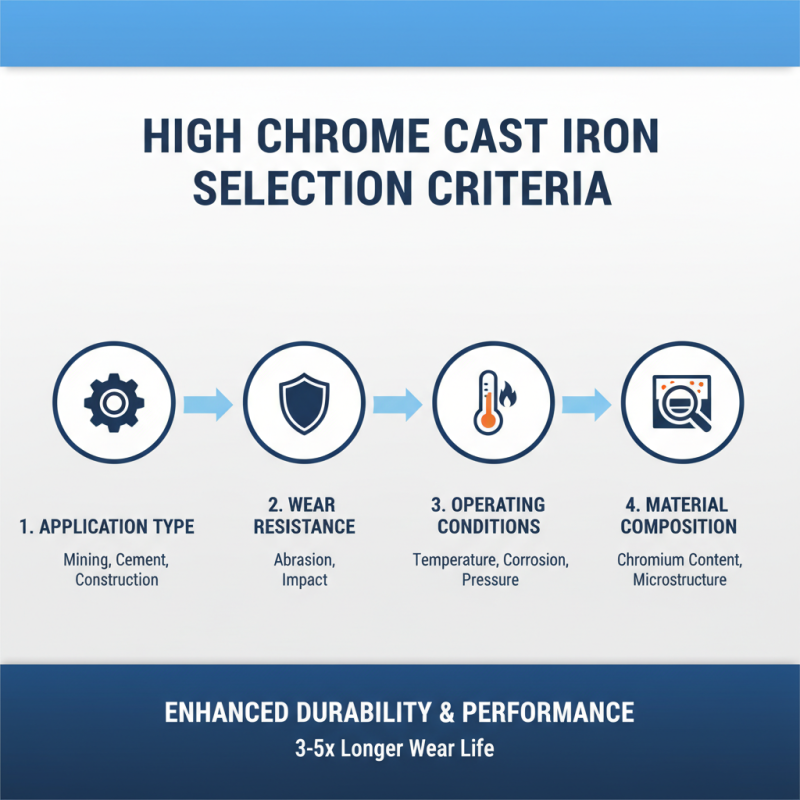

When selecting high chrome cast iron for specific applications, several critical criteria must be considered to ensure both performance and durability. High chrome cast iron, known for its outstanding wear resistance due to its high chromium content, is often favored in industries such as mining, cement, and construction. According to a recent industry report, components made from high chrome cast iron can achieve a wear life that exceeds traditional materials by up to 3-5 times, depending on the application and environmental conditions.

Factors such as the application's specific wear and corrosion resistance requirements, the operational environment, and temperature variations play significant roles in selection. For instance, a study by the International Journal of Material Science revealed that high chrome cast iron grades with 15-30% chromium perform exceptionally well in highly abrasive conditions, making them ideal for grinding media and pump housings. Furthermore, evaluating the casting process, such as whether to use sand casting or centrifugal casting, can impact the end material's integrity and longevity.

**Tip:** Always consult technical data sheets from manufacturers and conduct comparative analyses of wear resistance and hardness for different grades of high chrome cast iron before making a decision. Engaging with material specialists can provide insights into the best selection based on real-world case studies.

**Tip:** Periodic maintenance and monitoring during operation can significantly extend the life of high chrome cast iron components. Implementing a structured maintenance schedule can help identify wear patterns early, allowing for timely replacements and minimizing unexpected downtimes.

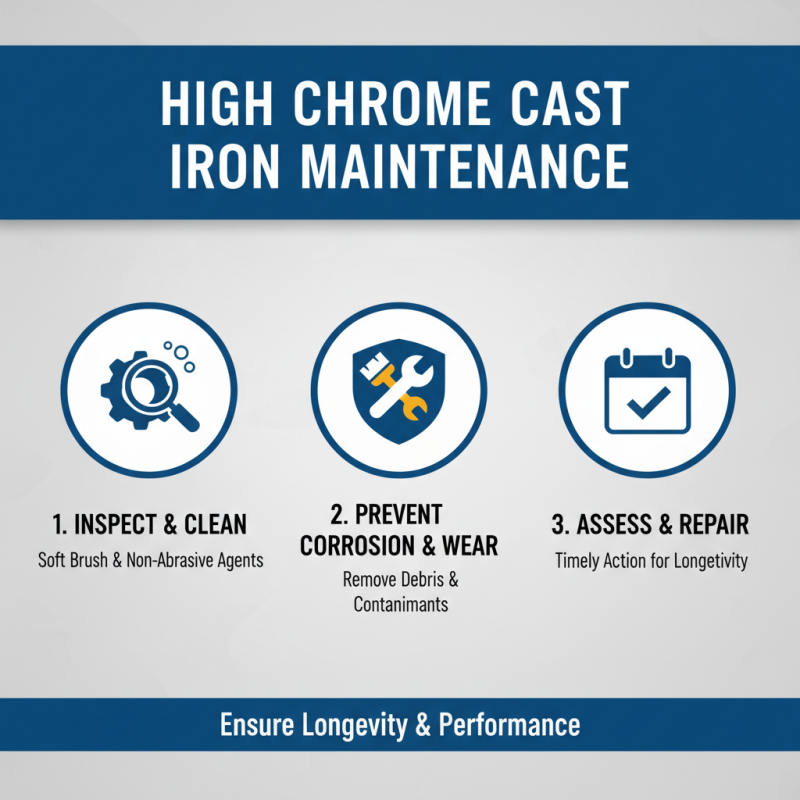

Maintenance of high chrome cast iron is crucial for ensuring its longevity and performance in various applications. One of the primary techniques involves regular inspection and cleaning to prevent the accumulation of debris and contaminants that can lead to corrosion and wear. Using a soft brush and non-abrasive cleaning agents helps maintain the surface integrity without scratching or damaging the material. It is also advisable to perform periodic assessments to identify any signs of wear or damage early on, allowing for timely repairs or replacements to avoid more significant issues.

Another effective maintenance technique is the application of protective coatings. These coatings can enhance the resistance to corrosion and abrasion while also providing a barrier against harsh environmental conditions. Regularly reapplying these coatings as part of a maintenance schedule can significantly extend the lifespan of high chrome cast iron components. Additionally, ensuring proper alignment and balance during installation can minimize unnecessary stress on the material, thus reducing wear. By incorporating these simple yet effective maintenance practices, users can optimize the durability and performance of high chrome cast iron in their operations.

High Chrome Cast Iron is prized for its exceptional wear resistance and durability, making it a popular choice in various industrial applications. However, maintaining its integrity can pose several challenges. One common issue is corrosion, often caused by harsh working environments or improper cleaning techniques. Over time, corrosive elements can compromise the material's durability, leading to increased wear and potential failure.

To effectively care for High Chrome Cast Iron, it’s essential to implement regular maintenance protocols. Tips for maintenance include ensuring that all surfaces are cleaned thoroughly to remove debris that might hold moisture. Applying protective coatings can also create a barrier against corrosive agents. Additionally, performing routine inspections can catch any signs of wear early, allowing for timely repairs that can extend the life of the material.

Another challenge is the brittleness that can develop in High Chrome Cast Iron, especially under extreme stress or impact. To mitigate this, operators should be mindful of load capacities and avoid sudden shocks that can lead to fractures. Using supportive structures during installation can also help in evenly distributing weight and reducing stress concentrations on the cast iron. By adhering to these practices, users can ensure the longevity and functional reliability of their High Chrome Cast Iron components.

When it comes to storing and handling high chrome cast iron products, proper practices can significantly enhance their lifespan and maintain their performance. High chrome cast iron, known for its high wear resistance and durability, benefits from specific storage conditions. According to a report from the American Foundry Society, humidity control is critical; maintaining a relative humidity of below 50% can prevent corrosion and moisture-related degradation. Adequate ventilation and temperature regulation in storage areas are also crucial to minimize rust formation and preserve the structural integrity of the cast iron.

When handling high chrome cast iron items, it is essential to use appropriate techniques to prevent stresses and impacts that could lead to cracks or fractures. As indicated in research conducted by the International Journal of Materials Engineering, utilizing foam padding or protective covers during transport can help absorb shocks and reduce the risk of damage. Furthermore, it is recommended to avoid dragging heavy items across surfaces, which can cause scratches or wear on both the cast iron and the surfaces they contact. Following these best practices in handling and storing can ensure that high chrome cast iron products remain reliable and efficient in their applications for years to come.