Leave Your Message

As we approach 2026, the casting industry is evolving rapidly. Innovations are reshaping the landscape of castings for casting. These advancements promise enhanced efficiency and precision in production. The latest materials and techniques make a significant difference in performance and sustainability.

One must consider the challenges that come with these innovations. Not all new methods yield the expected results. Sometimes, performance falls short of projections. Companies must adopt a mindset of experimentation and reflection to navigate these hurdles. Learning from failures is crucial for success in castings for casting.

Collaboration among industry players can drive meaningful change. Sharing knowledge and insights can lead to breakthroughs. Keeping an eye on emerging trends helps professionals adapt to a competitive market. It's an exciting time, yet the journey is filled with uncertainties.

The casting industry is on the cusp of significant transformation as we look towards 2026. Innovations in technology and processes are shaping how castings are produced. According to the latest market analysis, the global casting market is projected to reach $150 billion by 2026. This growth signals a robust interest in new methods and materials.

One notable trend is the shift towards additive manufacturing. This technology allows for more intricate designs and reduced material waste. Reports suggest that around 45% of casting companies plan to integrate additive techniques in their production processes. However, adopting new technologies can be challenging. Many manufacturers face a steep learning curve, which raises concerns about efficiency and quality control.

Sustainability is another hot topic. The industry is increasingly looking at eco-friendly materials and practices. A recent study indicated that 70% of casting facilities aim to decrease their carbon footprints by 2026. Yet, the transition often reveals issues with sourcing sustainable raw materials. There is a delicate balance between innovation and practicality that companies must navigate carefully.

| Casting Type | Material Innovations | Technology Trends | Sustainability Practices | Market Growth |

|---|---|---|---|---|

| Die Casting | Aluminum Alloys, Magnesium Alloys | 3D Printing Integration, Robotics | Recycling of Scrap Metal, Eco-Friendly Coatings | 8% CAGR |

| Sand Casting | Synthetic Sands, Biodegradable Materials | AI for Mold Design, Virtual Reality for Training | Reduction of Carbon Footprint, Local Sourcing | 6% CAGR |

| Investment Casting | Ceramic Shells, High-Performance Alloys | Smart Manufacturing, IoT Monitoring | Energy Efficiency, Waste Reduction Techniques | 7% CAGR |

| Gravity Casting | Ductile Iron, Special Alloys | Process Automation, Advanced Cooling Techniques | Use of Recycled Materials, Water Conservation | 5% CAGR |

The future of casting techniques by 2026 is becoming increasingly influenced by innovative materials. Advanced polymers and composites are taking the spotlight. These materials offer lightweight options that enhance durability. For instance, utilizing metal matrix composites can significantly reduce weight without sacrificing strength. Casting processes are adapting to incorporate these new materials, which often require specialized methods.

Sustainability is another key aspect. Eco-friendly materials are slowly entering the market. Biodegradable resins and recycled metals might not be mainstream yet, but awareness is growing. The challenge lies in balancing performance with environmental impact. Many manufacturers still rely on traditional methods and materials. This resistance to change can hinder progress.

However, the exploration of 3D printing is paving the way for unique techniques. It allows for rapid prototyping and custom designs. Some businesses invest in training to keep up with these innovations. Still, not all are ready to embrace this shift. There’s fear of the unknown and the complexities involved. The casting world is at a crossroads, embracing new materials while wrestling with the legacy of the past.

The casting industry is undergoing significant changes. Sustainability is becoming central to innovative practices. Eco-friendly methods are gaining traction. More companies are exploring the use of recycled materials. This shift reduces waste and conserves resources.

Biodegradable materials are making their mark. For instance, some manufacturers are experimenting with plant-based binders. These alternatives can minimize environmental impact. However, the transition is not without challenges. Availability of raw materials can limit widespread implementation. Additionally, the performance of these new materials needs thorough testing.

Another trend to watch is the energy-efficient processes in casting. Techniques that reduce energy consumption are emerging. These methods not only lower costs but also reduce carbon footprints. Yet, many manufacturers still rely on traditional processes. Overcoming inertia in such a well-established industry is tough. There's a need for a cultural shift toward sustainability. The path ahead requires a mix of innovation and reflection.

This chart illustrates the adoption trends of various eco-friendly innovations in the casting industry from 2023 to 2026. The data highlights the growing commitment to sustainability among manufacturers.

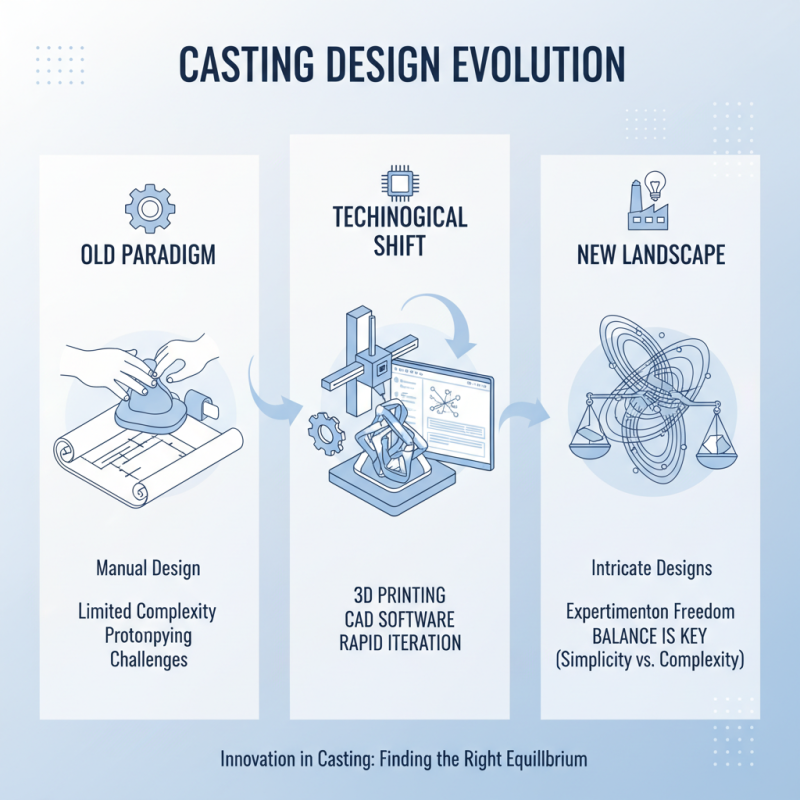

The landscape of casting design and production is rapidly transforming due to technological advancements. Techniques like 3D printing and computer-aided design (CAD) are revolutionizing how products are created. These innovations allow for intricate designs that were once impossible. Designers can now experiment freely, but this can also lead to overcomplicated solutions. Finding the right balance is crucial.

Moreover, automation is changing manufacturing processes. Robots can perform repetitive tasks faster and more accurately than humans. However, this also raises questions about workforce displacement. While efficiency increases, skilled labor may decline. There’s a need to rethink workforce training to adapt to this new reality.

Simulation software is also a game-changer. It allows engineers to predict outcomes before physical production. This reduces waste and saves time. Yet, relying too much on simulations can lead to oversight. A physical prototype is still necessary to validate designs. These advancements greatly impact the casting industry, pushing the boundaries of what is possible while also presenting new challenges.

As we look towards 2026, several industries are set to drive new casting trends and applications. The automotive sector is embracing lightweight materials. This shift aims to improve fuel efficiency. Engineers are experimenting with innovative alloys and composites. They aim to enhance durability while reducing weight. However, this transition is not without challenges. Finding the right balance between strength and weight is complex.

The construction industry is also evolving. Sustainable building materials are becoming paramount. Recycled metals and eco-friendly composites are in demand. These materials not only reduce environmental impact but also offer unique aesthetic properties. Yet, the industry often grapples with sourcing these materials in adequate quantities. This can slow down project timelines.

Meanwhile, the aerospace sector is pushing the boundaries of technology. Advanced casting techniques are enabling the creation of intricate designs. These intricate components help improve aircraft performance. However, quality control remains a significant concern. Variability in materials can lead to significant issues. Continuing to refine these processes will be key in driving innovations forward.