Leave Your Message

In the realm of industrial heating systems, the efficiency and longevity of boilers are paramount. Among the critical components that ensure optimal performance are the Boiler Tube Shields. These shields play a vital role in protecting boiler tubes from the adverse effects of heat, corrosion, and erosion, which are significant contributors to boiler failure. According to a report by the International Boiler and Pressure Vessel Code, inefficient heat transfer caused by tube wear can lead to performance losses exceeding 20%, emphasizing the importance of protective measures like boiler tube shields.

Recent advancements in materials and engineering have led to the development of innovative Boiler Tube Shields that not only enhance thermal performance but also prolong the lifespan of boiler systems. The 2021 Energy Efficiency Report highlighted that implementing advanced shielding solutions can result in energy savings of up to 15% annually for industrial facilities. Furthermore, these shields have been shown to reduce maintenance costs significantly, with some studies indicating a decrease of up to 30% in operational downtime related to tube failures. As industries strive for greater efficiency and reduced operational costs, the adoption of high-quality boiler tube shields is becoming increasingly essential.

High-quality boiler tube shields play a vital role in enhancing the efficiency and longevity of boiler systems. By providing a protective barrier against extreme temperatures, these shields help to minimize heat loss, ensuring that the energy generated is utilized more effectively. This not only boosts the overall performance of the boiler but also contributes to significant cost savings in fuel consumption. Furthermore, upgraded shields are engineered to withstand harsh conditions, reducing the need for frequent repairs and maintenance.

High-quality boiler tube shields play a vital role in enhancing the efficiency and longevity of boiler systems. By providing a protective barrier against extreme temperatures, these shields help to minimize heat loss, ensuring that the energy generated is utilized more effectively. This not only boosts the overall performance of the boiler but also contributes to significant cost savings in fuel consumption. Furthermore, upgraded shields are engineered to withstand harsh conditions, reducing the need for frequent repairs and maintenance.

Another key benefit of using superior boiler tube shields is their ability to prevent corrosion and wear. With constant exposure to steam and chemicals, boiler tubes are susceptible to deterioration over time. High-quality shields are designed with durable materials that resist rust and degradation, extending the lifespan of the boiler system. This proactive approach not only enhances operational efficiency but also aligns with sustainability goals by reducing waste generated from damaged equipment. Investing in robust boiler tube shields ultimately leads to improved performance and a more reliable energy system.

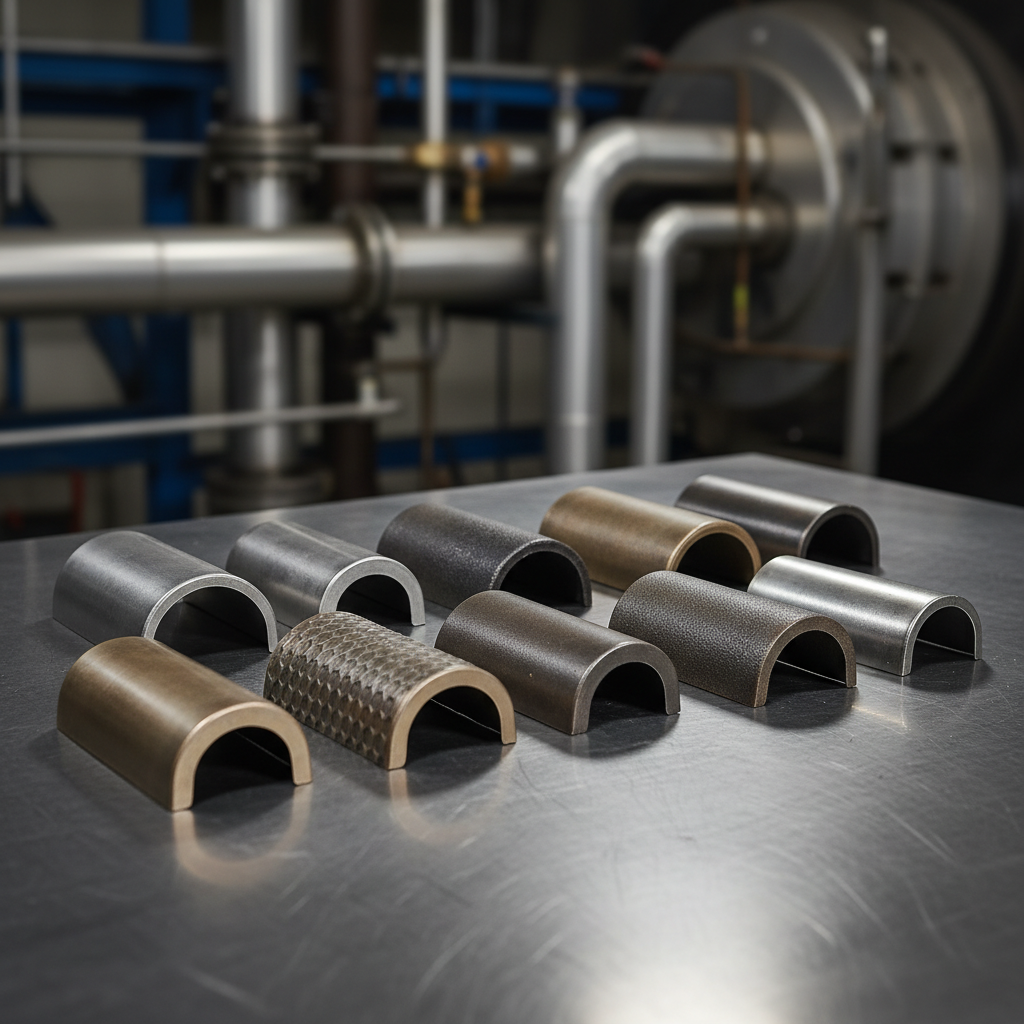

When selecting the best boiler tube shields, understanding key features is paramount for enhancing performance and ensuring longevity. The primary characteristic to consider is the material composition; high-quality shields are typically made from robust alloys or advanced composites that can withstand extreme temperatures and corrosive environments. According to a report by the American Boiler Manufacturers Association, using premium materials can increase the operational life of boiler tubes by up to 30%, significantly reducing maintenance costs.

Another crucial aspect to focus on is the thermal efficiency of the shields. Products that effectively minimize heat loss can improve overall energy efficiency by up to 15%, contributing to cost savings and environmental benefits. Attributes such as proper fit and ease of installation also play vital roles. A well-fitted shield not only enhances performance but also ensures that the insulation properties are optimized, thus maximizing heat retention.

**Tips:** When shopping for boiler tube shields, always prioritize those that offer technical specifications backed by industry standards. It’s also advisable to read reviews from other users and consult with professionals to ensure the product you choose aligns with your specific boiler requirements. Regular inspection and maintenance of the shields can further extend their lifetime and enhance overall efficiency.

| Shield Type | Material | Temperature Resistance | Thickness | Weight | Features |

|---|---|---|---|---|---|

| Standard Tube Shield | Stainless Steel | Up to 1200°F | 0.5 inch | 5 lbs | Corrosion Resistant |

| Advanced Insulation Shield | Ceramic Fiber | Up to 2300°F | 1 inch | 3 lbs | Lightweight, High Insulation |

| Heavy Duty Shield | Carbon Steel | Up to 1500°F | 0.75 inch | 8 lbs | Impact Resistant |

| Flexible Tube Shield | Silicone Rubber | Up to 500°F | 0.25 inch | 2 lbs | Easy Installation |

| High-Efficiency Shield | Aluminum | Up to 1000°F | 0.6 inch | 4 lbs | Energy Saving |

When selecting boiler tube shields, durability and material composition are paramount factors that directly influence performance and longevity. High-quality materials such as stainless steel, carbon steel, and advanced composites offer significant resistance to wear and thermal stress.

Stainless steel, in particular, is favored for its corrosion resistance, ensuring that shields can withstand harsh environments without compromising their structural integrity. The right choice of material not only extends the lifespan of the shields but also minimizes maintenance costs over time.

Moreover, the thickness and design of the tube shields play crucial roles in their protective capabilities. Thicker shields provide better insulation, protecting against heat loss and enhancing overall efficiency. Additionally, innovative designs that incorporate features like ventilation or improved fitting can optimize air circulation and reduce the risk of overheating. By carefully considering these material and design aspects, operators can ensure that their boiler systems run efficiently and safely, resulting in improved performance and reduced downtime.

In the realm of boiler tube shields, a comparative analysis of leading brands reveals significant variations in performance and protection. Key factors influencing the choice of boiler tube shields include material quality, durability, and ease of installation. Brands that prioritize high-quality materials often demonstrate superior resistance to high temperatures and corrosion, ensuring longer lifespan and reliability in demanding industrial environments.

Additionally, the market for boiler tube shields is evolving, mirroring trends observed in other protective equipment sectors. As seen with the mobile cases market, which is expanding rapidly due to increased consumer demand, the boiler tube shield segment is also likely to experience growth fueled by innovations in materials and design. Companies are focusing on enhancing their product offerings to provide better thermal efficiency and structural integrity, thus meeting the diverse needs of various industries. This competitive landscape encourages continuous improvement, helping consumers make informed choices based on performance metrics and protective capabilities.

When selecting boiler tube shields, user feedback is invaluable for assessing real-world performance. Many users report that high-quality shields significantly enhance thermal efficiency and reduce maintenance costs. For instance, several owners noted improved heat retention and extended tube life, highlighting the critical role that robust shielding plays in overall boiler performance. The right shield not only protects from corrosion and damage but also optimizes energy usage, leading to significant savings over time.

**Tips:** Consider the material and thickness of the shield when making your choice. Users suggest investing in shields made from durable alloys that resist harsh environments. Additionally, pay attention to user reviews focusing on ease of installation. Many users have shared their experiences with specific brands, noting that ease of application can save time and hassle during maintenance phases.

Moreover, consistent maintenance is key to realizing the full potential of these protective shields. Feedback from long-term users emphasizes the importance of regular inspections to detect any wear or damage early. By combining high-quality shields with diligent upkeep, boiler performance can be maximized, ensuring both efficiency and longevity in challenging operational conditions.