Leave Your Message

Choosing the right Boiler Tube Shields is crucial for ensuring the longevity and efficiency of your heating system. These protective barriers play a vital role in preventing corrosion and wear, ultimately saving you money. However, the selection process can be overwhelming. With so many options available, it's easy to make mistakes.

When selecting Boiler Tube Shields, consider the material and design. Different environments require different solutions. Think about temperature extremes and potential chemical exposure. Each scenario demands careful consideration. Sometimes, the most expensive option isn't the best choice. Cost-effectiveness should guide your decision.

Mistakes can lead to costly repairs down the line. Reflect on your needs before making a purchase. Asking the right questions is essential. Are the shields compatible with your existing system? Will they serve their purpose effectively? Take the time to explore your options and avoid hasty decisions. The right choice can greatly enhance the performance of your boiler system.

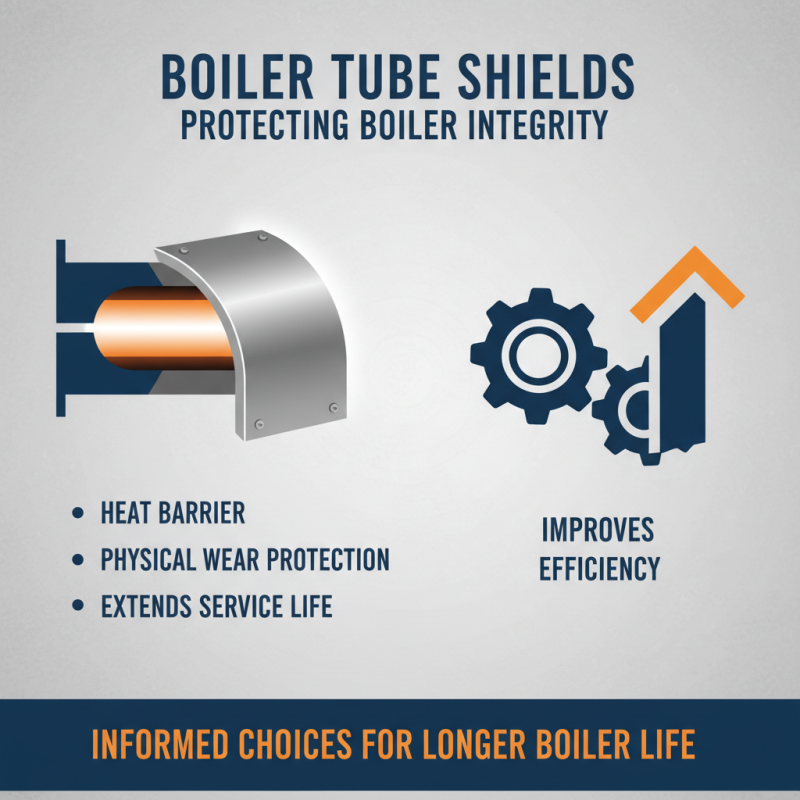

Boiler tube shields play a crucial role in protecting the integrity of boiler components. They provide a barrier against heat and physical wear. The right shield can improve efficiency and extend service life. Understanding their function is key to making informed choices.

Choosing the right boiler tube shields involves several considerations. Analyze the material quality; it significantly impacts durability. Look for shields that can withstand extreme temperatures and corrosion. Ensure they fit your specific boiler design. Compatibility is essential for effective protection.

Evaluate the installation process carefully. Complex installations can lead to mishaps or prolonged downtime. Seek user-friendly designs where possible. Also, consider maintenance requirements. Regular checks are vital to ensure they perform optimally. A neglected shield can compromise the entire boiler system over time.

Choosing the right boiler tube shields is crucial for effective performance and safety. Consider the environment where the boiler operates. If it faces high temperatures, select shields that can withstand extreme conditions. Analyze the material properties. Some materials can degrade faster than others. It’s essential to match the shield with operational requirements.

Look for durability and resistance to corrosion. A good shield protects the boiler tubes from wear and harsh chemicals. Think about the installation process. Some shields require special tools or expertise to install. Gaps in installation can lead to significant issues later. Verify the shield’s compatibility with existing boiler components as well.

Another aspect to ponder is maintenance. Some shields are easier to clean than others. Regular maintenance can prolong their lifespan. Consider the cost-effectiveness too. Balancing the price with performance is crucial. Investing in high-quality shields may reduce long-term costs. When selecting boiler tube shields, the details matter greatly. Each decision impacts overall efficiency. Reflect on these factors carefully. Make the best choice for your specific needs.

| Key Factor | Description | Importance Level | Considerations |

|---|---|---|---|

| Material Type | Choose corrosion-resistant materials like alloy steel or stainless steel. | High | Check compatibility with the operating environment. |

| Thickness | Adequate thickness to withstand impacts and heat. | Medium | Consider operating temperature and pressure. |

| Size Compatibility | Ensure shields fit correctly to prevent gaps. | High | Measure the boiler tubes accurately. |

| Heat Resistance | Select materials that can handle the maximum temperature. | High | Refer to the boiler specifications. |

| Ease of Installation | Consider user-friendliness in installation and maintenance. | Medium | Check for comprehensive installation guides. |

| Cost | Evaluate the total cost against budget constraints. | Medium | Consider long-term durability vs. initial investment. |

| Supplier Reliability | Assess the reliability and reputation of suppliers. | High | Look for customer reviews and testimonials. |

| Warranty | Opt for shields with a solid warranty or guarantee. | Medium | Check length and coverage of the warranty. |

| Environmental Considerations | Choose eco-friendly materials and practices if possible. | Low | Research sustainability practices in manufacture. |

| Regulatory Compliance | Ensure that the shields meet industry standards and regulations. | High | Verify certifications and compliance documentation. |

When selecting boiler tube shields, material choice is crucial. Different materials offer varying durability and resistance to heat. Common options include stainless steel, aluminum, and carbon fiber composites. Stainless steel is strong but can be heavy. Aluminum is lighter but may not withstand extreme temperatures as well. Carbon fiber offers excellent heat resistance but can be expensive. Understanding the specific operating conditions of your boiler is essential.

Durability often hinges on the shield's thickness and overall design. Thicker shields may offer better protection but can also add to the weight and installation complexity. In some cases, a thinner shield might suffice, especially in less demanding environments. However, cutting corners on material quality can lead to premature failures.

Consider potential wear over time. Scratches, dents, and corrosion can compromise a shield's effectiveness. Regular maintenance and inspections are vital. You might overlook minor damages, thinking they are inconsequential. Yet, even small issues can escalate into significant problems if not addressed early. The right balance between weight, cost, and durability is often difficult to achieve, and reflection on past choices can lead to better decisions in future projects.

Choosing the right boiler tube shields is crucial. One key factor is compatibility with existing boiler systems and components. Before making a decision, understand the specifications of your current setup. Compatibility ensures longevity and efficiency. Misalignment can cause leaks or failures.

When selecting shields, inspect material types. They should match your boiler’s requirements. If not, performance may suffer. Look for shields that can withstand high temperatures and pressures. This reduces future maintenance issues. Also, factor in installation compatibility. Sometimes modifications may be needed.

Don’t forget to seek expert advice. Consult engineers or technicians familiar with your boiler system. They might provide insights you overlook. Consider the entire system ecosystem. A great shield alone won't solve all problems. It needs to work in harmony with existing parts. Remember, mistakes can be costly. A wrong choice may lead to repairs that are both time-consuming and expensive.

When selecting boiler tube shields, maintenance and lifespan stand out as critical factors. Poor maintenance can lead to premature failure. Regular inspections are essential to catch issues early. Look for signs of wear, corrosion, or loss of material. Ignoring these indicators can result in costly repairs.

One useful tip is to choose materials that are resistant to high temperatures. This can significantly extend the life of the shields. Another consideration is the environment where the boiler operates. Moisture, for instance, can negatively impact durability. Ensure proper ventilation around the boiler system to minimize damage from humidity.

Finding the right balance between cost and durability is also vital. Cheaper options may not offer the longevity you need. Investing in quality shields might seem excessive but can save money in the long run. Understand that each decision can affect performance and efficiency. Keeping up with maintenance routines will ultimately pay off.