Leave Your Message

When embarking on a new project, one of the most crucial aspects to consider is sourcing the right materials, and for many projects, this means selecting the best castings for casting. Whether you are working on a small-scale artistic creation or a large industrial component, finding quality castings can significantly influence the overall outcome. The diverse range of materials and techniques available today means that making informed choices is essential for ensuring durability, functionality, and aesthetic appeal in your final product.

Navigating the world of castings requires an understanding of the various types available and their respective properties. Factors such as the intended use, environmental conditions, and desired finish can all impact your selection process. Therefore, gaining insights into industry best practices and expert recommendations can serve as invaluable resources in your quest for the ideal castings for casting. In this guide, we will explore top tips to assist you in identifying and acquiring the best castings that align with your project’s unique requirements, helping you achieve your vision with confidence and precision.

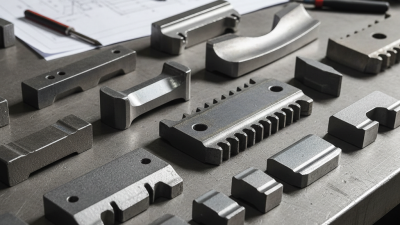

When embarking on a project involving castings, it's essential to have a solid grasp of the various types available. Each type of casting material, whether aluminum, iron, or zinc, offers unique properties that suit different applications. Aluminum castings are known for their lightweight and corrosion resistance, making them ideal for automotive and aerospace industries. In contrast, iron castings provide excellent wear resistance and are typically used in heavy machinery and construction projects. Understanding these distinctions can help you select the best material for your project's specific needs.

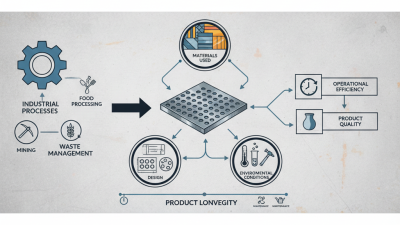

One of the top tips for finding the best castings is to evaluate the project's requirements carefully. Consider factors such as strength, weight, and environmental exposure. For instance, if your project requires high strength-to-weight ratios, aluminum may be a better choice than iron. Additionally, the casting process you choose can greatly affect the final product. Techniques like sand casting, investment casting, and die casting each have their advantages and limitations, depending on the complexity of the design and the intended use.

Another crucial tip is to collaborate closely with your casting supplier. Discussing your project's goals and specifications in detail can lead to valuable insights about the best materials and methods to adopt. Suppliers often have extensive experience and can recommend solutions that you may not have considered. By leveraging their expertise, you can enhance the feasibility and performance of your final casting product.

When selecting castings for your next project, evaluating material properties is critical to ensure that the final product meets the required standards. Strength is often the foremost consideration, as it determines how much stress the casting can handle without failure. Depending on the application, different casting materials exhibit varying levels of tensile and compressive strength. For instance, materials like aluminum may offer lightweight solutions with good strength-to-weight ratios, while steel might be chosen for applications requiring higher strength and toughness.

Durability is another essential factor, particularly for projects exposed to harsh environments or wear and tear. The material's resistance to corrosion, abrasion, and thermal fatigue can significantly impact its longevity. For example, castings made from high-quality alloys typically exhibit better performance under stress and adverse conditions. Additionally, considering cost is paramount; while high-strength and durable materials may come with a more significant initial investment, their longevity and performance may result in lower lifecycle costs. Balancing these properties—strength, durability, and cost—can lead to more informed decisions, ensuring the chosen material aligns with both project requirements and budget constraints.

When it comes to selecting the best castings for your next project, it's crucial to analyze the manufacturing processes to ensure optimal outcomes. Each casting type has its unique manufacturing techniques, such as sand casting, die casting, and investment casting, all of which influence the final product's quality and suitability. According to a recent market analysis, the global metal casting market is expected to reach USD 232.6 billion by 2028, growing at a CAGR of 5.9% from 2021. This growth is driven by advancements in manufacturing technologies and materials that enhance casting performance.

To make the most informed decision, consider the specific requirements of your project, such as mechanical properties, tolerance levels, and surface finish. For instance, investment casting is preferred for complex geometries and tight tolerances, while sand casting is often more cost-effective for larger components. Ensure that you assess the technical specifications and capabilities of the casting process to match your project needs precisely.

Tip: Always conduct a thorough cost-benefit analysis when selecting casting processes. While some methods may appear cheaper upfront, the long-term benefits of quality and durability can outweigh initial savings. Additionally, consult industry technical reports and engage with experts to gather insights on the latest innovations and practices in casting that can significantly impact your project's success.

This chart demonstrates the most common manufacturing processes used for casting metals, highlighting their prevalence in modern projects. Each bar represents the percentage of usage for each casting method.

When searching for the best castings for your next project, assessing supplier credentials becomes a crucial step that should not be overlooked. Certification and quality assurance standards serve as key indicators of a supplier's capability to deliver high-quality products consistently. Suppliers that comply with recognized industry certifications, such as ISO standards, demonstrate a commitment to maintaining stringent quality processes and operational excellence. This not only ensures that you receive castings that meet your specifications but also minimizes the risk of unexpected failures during the production process.

In addition to certifications, it’s important to evaluate the supplier's quality assurance practices. A robust quality assurance program should encompass all stages of production, from material selection to final inspection. Look for suppliers who utilize advanced testing methods and equipment to verify the integrity of their castings. Regular audits by third-party organizations can provide further assurance of their adherence to quality standards. By prioritizing these credentials, you can build a reliable supply chain that enhances the overall success of your project.

| Supplier Type | Certification | Quality Assurance Standards | Lead Time (Weeks) | Sustainability Practices |

|---|---|---|---|---|

| Foundry A | ISO 9001 | ASTM Standards | 6 | Recycling Program |

| Foundry B | ISO 14001 | API Standards | 8 | Carbon Neutral |

| Foundry C | OHSAS 18001 | ISO/TS 16949 | 5 | Water Conservation |

| Foundry D | ISO 50001 | EN Standards | 7 | Green Energy Usage |

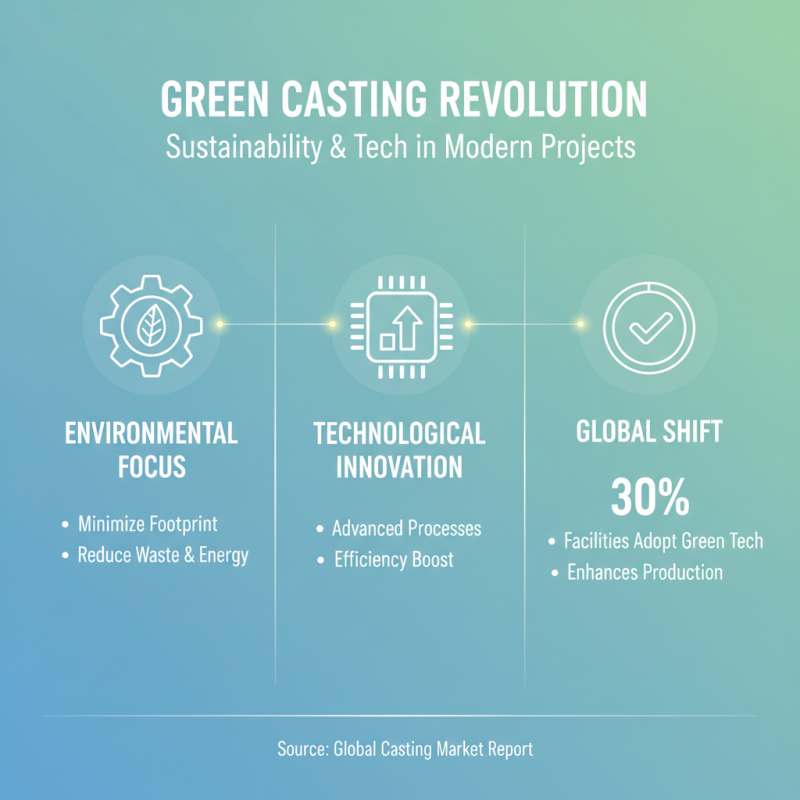

Incorporating sustainability and technological innovations in casting has become paramount for modern projects. As industries continue to grapple with climate change implications, casting processes are evolving to minimize environmental impact. According to a report by the Global Casting Market, nearly 30% of casting facilities have adopted green technologies that reduce energy consumption and waste. This shift not only addresses sustainability concerns but also enhances the overall efficiency of the production process.

When seeking the best castings, it’s essential to consider the latest trends in sustainable materials. Utilizing recycled metals not only lowers the carbon footprint but also meets growing consumer demand for eco-friendly products. Besides, advancements such as 3D printing in casting have revolutionized the industry, allowing for more intricate designs with less material waste. One effective tip is to collaborate with suppliers who prioritize sustainable practices and can provide documentation on their environmental efforts.

Moreover, staying informed about technological innovations in the casting field is critical. The integration of smart manufacturing technologies, such as IoT and AI, is optimizing production schedules and reducing lead times. Engaging in workshops or industry forums can keep you updated on these developments. Another tip is to evaluate the lifecycle of your casting materials, ensuring that your selections align with both quality standards and the movement towards sustainability. Emphasizing these elements can significantly enhance the success and acceptance of your next casting project.