Leave Your Message

Refractory materials play a crucial role in various industrial applications, forming the backbone of processes that require resistance to high temperatures, chemical corrosion, and mechanical wear. These materials are designed to withstand extreme thermal conditions, making them indispensable in sectors such as steel manufacturing, petrochemicals, cement, and glass production. Dr. Emily Carter, a leading expert in materials science, once stated, "The value of refractory materials lies not only in their thermal resistance but also in their ability to enhance process efficiency and sustainability." This highlights the integral role that refractory materials have in promoting both operational effectiveness and environmental responsibility.

As industries continue to evolve, the demand for advanced refractory solutions grows, leading to innovations that not only meet the traditional requirements but also address modern challenges. By understanding the properties, classifications, and applications of refractory materials, industries can improve their productivity and reduce their environmental footprint. This makes it essential to appreciate the significance of refractory materials and explore their vital contributions to industrial processes, underpinning their importance in a rapidly changing technological landscape.

Refractory materials are defined as substances that are resistant to high temperatures, making them essential in various industrial applications. These materials can withstand extreme heat, mechanical stress, and corrosive environments, which makes them suitable for use in furnaces, kilns, reactors, and other high-temperature settings. The primary characteristic of refractory materials is their ability to maintain structural integrity and performance when exposed to temperatures that can exceed 1,500 degrees Celsius (2,732 degrees Fahrenheit). Their thermal stability is crucial in preventing degradation or failure during operation.

In addition to high-temperature resistance, refractory materials also exhibit low thermal conductivity, which helps in conserving energy and improving efficiency within industrial processes. They possess excellent chemical resistance, providing protection against harsh environments and minimizing wear from corrosive substances. Furthermore, refractory materials are typically classified into several categories, including acidic, basic, and neutral refractories, each with specific properties suited for particular applications. This versatility underscores their importance in industries such as metallurgy, ceramics, and petrochemicals, where reliable performance under demanding conditions is paramount.

| Property | Description |

|---|---|

| Melting Point | Refractory materials have high melting points, typically above 1500°C (2732°F). |

| Thermal Conductivity | These materials generally have low thermal conductivity, which helps in thermal insulation. |

| Chemical Stability | Refractory materials are resistant to chemical corrosion and oxidation. |

| Mechanical Strength | They maintain strength and structural integrity at high temperatures. |

| Applications | Used in furnaces, kilns, incinerators, and reactors across various industries. |

| Types | Types include clay, high alumina, silica, and magnesia based refractories. |

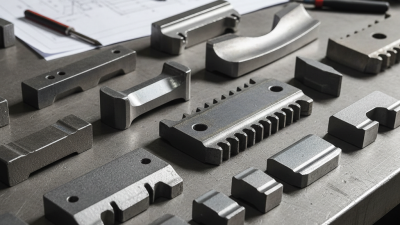

Refractory materials are essential in various industrial applications due to their ability to withstand high temperatures and corrosive environments. They are classified into several types, each suited for specific uses based on their thermal and chemical properties. The most common types include ceramics, metals, and glass, with ceramics being the most widely utilized due to their excellent thermal stability and resistance to wear. These materials are often employed in furnaces, kilns, and reactors, where they protect structures from extreme heat and facilitate efficient thermal processes.

In addition to ceramics, there are also specialized refractory products such=": #007BFF;">silica and alumina refractories, which are used in steel and cement industries for their ability to endure high temperatures while maintaining structural integrity. Insulating refractories are designed for thermal efficiency, helping reduce energy consumption in high-temperature operations. Another category includes fireclay refractories, which are often used in lining applications due to their good thermal shock resistance. The diverse range of refractory materials allows industries to select the most appropriate type based on precise temperature requirements and operational conditions, ultimately contributing to improved efficiency and safety in high-temperature processes.

Refractory materials play a critical role in high-temperature industries such as metal production, cement, and ceramics. They are designed to withstand extreme conditions, typically exceeding temperatures of 1500°C (2732°F), and protect equipment from thermal shocks and corrosive environments. According to a report by Grand View Research, the global refractory materials market size was valued at approximately $27.2 billion in 2020 and is expected to grow at a CAGR of 2.8% through 2028, emphasizing the increasing demand for these materials in various industrial applications.

The importance of refractory materials is particularly highlighted in steel manufacturing and non-ferrous metal production, where their ability to maintain structural integrity under high thermal stress is essential for operational efficiency. For instance, refractory linings in furnaces can significantly reduce the risk of wear and prolong equipment life, which in turn lowers maintenance costs. A study conducted by the Refractories Institute found that using high-quality refractories can enhance energy efficiency by reducing heat loss, leading to potentially significant cost savings in energy consumption.

Tips: When selecting refractory materials, it is crucial to consider factors such as thermal conductivity, chemical composition, and mechanical strength. Additionally, ensure that the chosen materials are suitable for the specific application and environmental conditions to maximize performance and longevity. Regular inspections and maintenance schedules for refractory linings can also help identify potential issues early, preventing costly downtimes and ensuring smooth operations.

Refractory materials are crucial in various industrial processes, primarily due to their unique properties that enable them to withstand extreme conditions. One of the key characteristics of refractory materials is their high melting point, which allows them to maintain structural integrity even in the most demanding environments, such as furnaces and reactors. This property prevents deformation and ensures that the materials can perform their functions without failing, which is essential for efficiency and safety in industrial operations.

In addition to high melting points, refractory materials exhibit excellent thermal stability and resistance to thermal shock. This means they can endure rapid temperature changes without cracking or breaking, a critical factor in industries that involve cyclical heating and cooling processes. Moreover, their chemical inertness is vital, as it minimizes reactions with molten metals, slags, and gases, thereby protecting equipment from degradation. These properties collectively make refractory materials indispensable in sectors like metallurgy, ceramics, and energy production, where reliability and performance under extreme conditions are paramount.

The following bar chart illustrates the significance of different properties of refractory materials as rated by industry professionals. These properties are essential for ensuring efficiency and durability in high-temperature environments.

The development and application of refractory materials present several significant challenges that impact their functionality and performance in various industries. One of the primary challenges is the high cost of raw materials and production processes associated with refractory materials. According to a report by MarketsandMarkets, the global refractory materials market is expected to grow from USD 23.3 billion in 2020 to USD 32.7 billion by 2025, highlighting the increasing demand while simultaneously illustrating the rising costs that manufacturers face. This price volatility can limit accessibility for smaller players in the market, affecting innovation and diversification in product offerings.

Another critical challenge lies in the performance under extreme conditions. Refractory materials must withstand high temperatures and harsh chemical environments, leading to increased wear and failure rates over time. A study from the International Journal of Applied Ceramic Technology emphasized that the development of refractory materials with enhanced thermal stability and resistance to thermal shock is crucial to meet industrial demands. Additionally, issues such as porosity can adversely affect the mechanical strength and thermal conductivity of refractories. Innovating and optimizing formulations to mitigate these problems requires ongoing research and significant investment in material science. Thus, addressing these challenges is essential for sustaining the growth of the refractory materials sector in diverse industries, including steel, ceramics, and glass manufacturing.